Biomass and Carbon Fuels in Metallurgy: A Revolutionary Path to Sustainable Metal Production

4 out of 5

| Language | : | English |

| File size | : | 40452 KB |

| Print length | : | 292 pages |

The modern world relies heavily on metals for various applications, from construction to electronics. However, traditional metal production methods often result in substantial carbon emissions and environmental degradation. To address these challenges and achieve sustainability goals, the industry is embracing innovative approaches involving biomass and carbon fuels in metallurgy.

Biomass: A Renewable Energy Source

Biomass refers to organic matter derived from plants, trees, and agricultural residues. It plays a significant role in metallurgy as a renewable energy source and an alternative to fossil fuels. Biomass combustion provides heat and energy for various metallurgical processes, including smelting, forging, and heat treatment.

Biomass gasification, a thermochemical process, converts biomass into a fuel gas called syngas. Syngas can be used as an energy source or a reducing agent in metallurgical processes, replacing traditional fossil fuels. This approach reduces carbon emissions and fosters a circular economy by utilizing waste biomass.

Carbon Fuels: Unlocking Carbon Neutral Metallurgy

Carbon fuels, such as charcoal, coke, and biochar, play a crucial role in metallurgy as reducing agents and sources of carbon for alloying. Traditional carbon fuels contribute to carbon emissions, but advancements are being made towards carbon-neutral metallurgy.

Biochar, a charcoal-like substance produced from biomass, offers a sustainable alternative to fossil-based carbon fuels. Biochar can be used as a reducing agent in metallurgical processes, capturing and storing carbon dioxide. This approach creates a closed-loop system, sequestering carbon rather than releasing it into the atmosphere.

Applications in Metallurgy

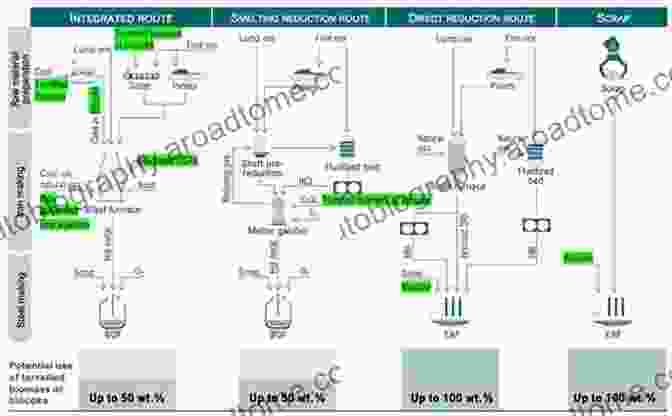

Biomass and carbon fuels are gaining widespread applications in metallurgy, transforming various processes. Here are a few examples:

- Smelting: Biomass gasification systems provide heat and syngas for smelting, reducing energy consumption and emissions.

- Forging: Biomass-fired furnaces heat metals for forging, minimizing the use of fossil fuels.

- Heat Treatment: Biomass boilers generate heat for heat treatment processes, reducing reliance on non-renewable energy sources.

- Iron and Steel Production: Biomass gasification and biochar utilization contribute to carbon-neutral iron and steel production, mitigating emissions.

Benefits of Biomass and Carbon Fuels in Metallurgy

The integration of biomass and carbon fuels in metallurgy offers numerous benefits:

- Reduced Carbon Emissions: Biomass and carbon fuels foster carbon-neutral metallurgy, significantly reducing greenhouse gas emissions.

- Energy Efficiency: Biomass gasification systems provide energy-efficient heat and syngas, minimizing energy consumption.

- Renewable Energy Utilization: Biomass offers a renewable energy source for metallurgy, reducing dependence on fossil fuels.

- Circular Economy: Biomass and biochar utilization promote a circular economy by utilizing waste materials and sequestering carbon.

Challenges and Future Prospects

While the use of biomass and carbon fuels in metallurgy holds great promise, challenges exist:

- Biomass Supply Chain: Ensuring a sustainable and reliable supply of biomass is crucial for widespread adoption.

- Cost Competitiveness: Biomass and carbon fuels may require additional investments compared to traditional methods.

- Technological Development: Further research and development are needed to optimize biomass gasification and biochar utilization processes.

The future of biomass and carbon fuels in metallurgy is promising. Ongoing research, collaborations, and government initiatives aim to address challenges and accelerate the transition towards sustainable metal production.

Biomass and carbon fuels are revolutionizing metallurgy by unlocking sustainable and energy-efficient practices. Their integration fosters carbon-neutral production, utilizes renewable energy sources, and promotes a circular economy. As the industry continues to innovate, biomass and carbon fuels will play an increasingly vital role in creating a sustainable future for the metal production sector.

4 out of 5

| Language | : | English |

| File size | : | 40452 KB |

| Print length | : | 292 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Deborah Levy

Deborah Levy Jan Yager

Jan Yager Phyllis Peterson

Phyllis Peterson Nick Bamford

Nick Bamford Jennifer Worick

Jennifer Worick William J Hirsch Jr

William J Hirsch Jr Mike James

Mike James Paramahansa Yogananda

Paramahansa Yogananda Chet Van Duzer

Chet Van Duzer Daniel Pratt

Daniel Pratt Mauro De Santis

Mauro De Santis Roberto Verganti

Roberto Verganti John Stewart

John Stewart Robert S Hanmer

Robert S Hanmer Eva M Selhub

Eva M Selhub Rebecca Solnit

Rebecca Solnit Dr Will Taegel

Dr Will Taegel Reen Rose

Reen Rose Steve Coll

Steve Coll Patrick Kua

Patrick Kua

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Aaron BrooksFollow ·7.4k

Aaron BrooksFollow ·7.4k Jamie BellFollow ·6.3k

Jamie BellFollow ·6.3k Felix CarterFollow ·2.8k

Felix CarterFollow ·2.8k Doug PriceFollow ·2.2k

Doug PriceFollow ·2.2k Cody RussellFollow ·5.5k

Cody RussellFollow ·5.5k Fletcher MitchellFollow ·12.6k

Fletcher MitchellFollow ·12.6k Duncan CoxFollow ·12.8k

Duncan CoxFollow ·12.8k Gerald BellFollow ·13.5k

Gerald BellFollow ·13.5k

Nathan Reed

Nathan ReedProgress In Complex Systems Optimization Operations...

This book presents...

Duncan Cox

Duncan CoxHSK Chinese Grammar: The Ultimate Guide to Master Chinese...

HSK Chinese...

Owen Simmons

Owen SimmonsDevelopment and Applications in Policy Support...

Unveiling the Transformative...

Travis Foster

Travis FosterTransform Emotions Into Energy To Achieve Your Greatest...

Do you feel like your...

Joe Simmons

Joe SimmonsUnlocking the Frontiers of Artificial Intelligence: Delve...

In the annals of artificial...

4 out of 5

| Language | : | English |

| File size | : | 40452 KB |

| Print length | : | 292 pages |